What is GMP?

Good Manufacturing Practice (GMP) standards are required by regulators. They are a set of guidelines which ensure pharmaceutical products and services are consistent and controlled. By following these standards, we can ensure the products we provide are functional and safe for our customers, and ultimately patients. All stages of the product lifecycle are included in the GMP standards, from development and raw materials to the production process, quality control, and how the product can be stored and delivered. The GMP guidelines show that a company is manufacturing pharmaceutical excipients to a certain standard, as authorized by approved certifications. Our manufacturing process and products completed a comprehensive audit with EXCiPACT™ – showing that they meet GMP standards (EXCIPACT.org). We can therefore provide media and reagents tailor made to both your research or manufacturing needs while also specific to your regulatory requirements.

Although regulatory requirements are not needed until a product is being considered for clinical use, it is important to begin considering whether your product will meet GMP standards from the beginning. Transitioning from non-compliant to compliant products at later stages of the development timeline can be costly and time consuming, and it may not be possible to scale-up from non-compliant media. By starting your research using GMP certified products, stumbling blocks later down the path are eliminated and you can research and develop your pharmaceutical pipeline with no concerns about regulatory standards of media and reagents. Learn more about our GMP certification.

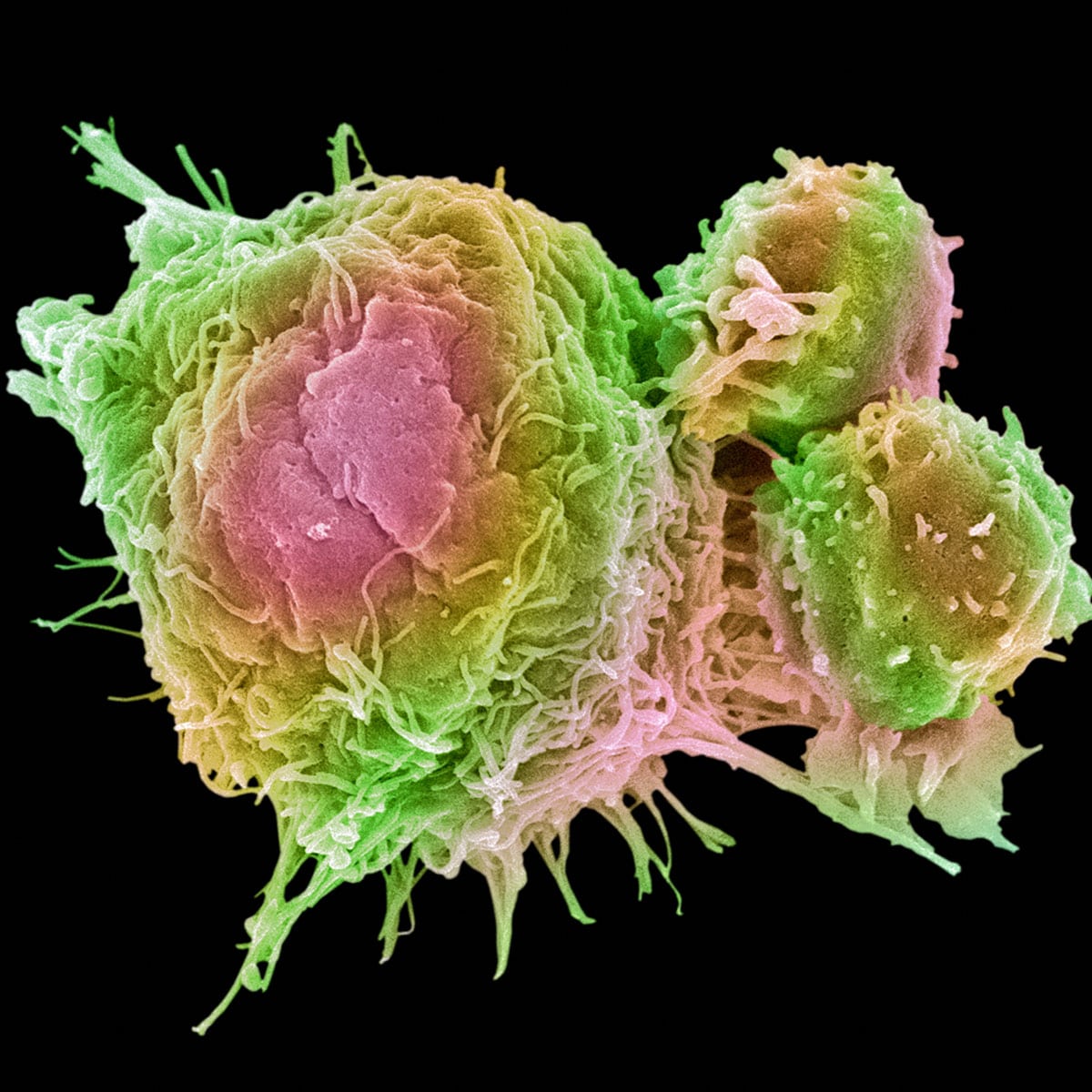

Drug discovery in cancer research

Cancer research is of particular relevance when anticipating regulatory requirements. Cell culture is an essential step when developing, manufacturing and commercializing cell-based therapies, which are the basis of many cancer treatments in development today (Rafei, 2019). Cell-based cancer therapies including engineered T-cell receptors, chimeric antigen-receptor (CAR)-T cells, tumor-infiltrating lymphocytes (TILs) and natural killer cells are at the forefront of innovation in cancer research (Rafei, 2019). The first immunotherapy for cancer treatment became commercially available in 2017, and there are still numerous challenges in the development of immunotherapies across the spectrum of cancers. These include finding appropriate targets, antigen loss, problems with developing therapies specific to an individual patient, and toxicity. The latter includes immunotherapy specific adverse events such as cytokine release syndrome and neurological events (Rafei, 2019). These complex issues all rely on the fundamental cell-based technology underpinning the therapy. Failing to plan for commercialization of cell-based therapies can result in costly and time-consuming challenges when moving through regulatory processes.

The raw materials used to research cell-based cancer therapies – particularly the choice of media – can introduce significant variability in the manufacturing process. This variability can negatively affect cell growth, viability and the specific productivity or quality of an expressed protein (McGillicuddy, 2018).

Preclinical cancer research often uses cell lines in medium and FCS, which results in high lot-to-lot fluctuation and many potential non-standardized components. In the early stages of development, a researcher may be focused on optimizing the functionality of the medium to enable the desired cell expansion, phenotype, cell viability and functionality. However, at later stages of the process when the product is transitioning from preclinical to clinical stages, regulatory requirements may not allow the pre-defined protocol to be used if products within it do not meet GMP standards. In addition, it is possible to choose a medium that works at smaller scales but doesn’t scale-up. One example of issues with scale is use of a serum-containing medium, which introduces issues with supply limitations, cost, high lot-to-lot variation and safety issues when scaling. Therefore, choosing a serum-free serum is important.

Medium selection at the beginning of the cancer research process is crucial.

Standardize cancer research from the beginning

To prevent complications from non-GMP standard products, work with standardized media for multiple cell lines. Focusing on the quality of the medium ensures reliable results and saves time and money.

Although GMP standards may not be required in the earliest stages of research, they will be required at later stages. Working with us will ensure the products you use are GMP compliant and all the regulatory documentation you require is available.

References

1. https://www.excipact.org/

2. McGillicuddy N, Floris P, Albrecht S, Bones J. Examining the sources of variability in cell culture media used for biopharmaceutical production. Biotechnol Lett 2018;40(1):5-21

3. Rafei H, Mehta R, Rezvani K. Editorial: Cellular Therapies in Cancer. Front Immunol 2019;10:2788